From tree to plank

It all starts with the tree itself, which is de-branched, cut into three sections – the butt lock, middle log and top log. These logs are then taken to the sawmill, where the decking boards are sawn and then, depending on the species, kiln-dried in order to improve stability by reducing the moisture content inside the wood.

To give the plank its distinct decking profile, the sawmill will then run the planks through a moulder such as the one seen in the video above. This creates the final planed product, which is then shipped out and sold to decking providers across the country in sizes that generally range between 19mm and 40mm in thickness and 90mm and 190mm in width.

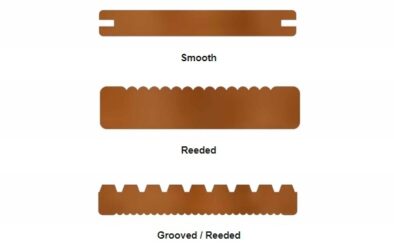

Decking Profiles

The three main types of decking surface: smooth, reeded or grooved.

Note that reeded decking can be quite slippery when wet, so if you go for this option you might want to invest in some extra anti-slip inserts.

Treatment

As most joists and decking are made of softwood, which is (as the name suggests) not quite as rugged as its hardwood brethren, extra treatment is often needed to increase its durability or service life, that is the number of years it will last for its original purpose. There are a number of treatments, mostly divided into two groups: chemical or heat modifications.

Chemical pressure impregnation is a process that forces chemicals deep into the wood using a vacuum cylinder. The current chemical biocide used is Copper, although in the past Chromium and even Arsenic used to be the norm! Don’t forget to seal the ends of any impregnated timber you cut with a proper sealer as the newly sawn surface revealed by your cut is no longer protected.

Thermo modification meanwhile, uses heat and steam to change the structure of the wood and increase its durability. The process uses no chemicals and the final result is a darker coloured timber that has much less moisture so it is also much more stable.

Chemical modification might improve the durability of the wood but it is environmentally wasteful and can look cheap. Thermodified wood, meanwhile, is a more eco-friendly alternative to standard impregnated timbers that uses a careful combination of heat and vapour to create a stable and pleasant finished product.

There is however a new alternative that has found the coveted middle ground: OrganoWood. This Nordic technology has found a way to use the same impregnation technique but uses a natural Silica solution instead of the standard harsh Copper-based solutions. The end result is a fossilised timber that is not as brittle as Thermo Wood, has virtually the same service life as biocide Copper impregnation yet is environmentally friendly. It also weathers to a beautiful silver-grey much quicker and consistently.

What to consider when building a deck

When building a new decking structure, there are several factors to take into consideration:-

Type

What is the look you’re after? Rustic knotty Pine or swish Ipe? From FSC certified hardwood, including marine decking, to thermochemical modified softwood as well as composite and recycled plastic decking, we offer a complete range of options catering for every individual need. When settling on an option, take into account the size of the project, the local environment and traffic and, of course, your budget. If you need help with any of those variables along the way, just give us a ring and we’ll be happy to assist you.

Durability

How long is it expected to last? This is the criteria where budget has the biggest impact as pressure impregnated softwoods are usually the cheapest but also the less durable option. Still, as long as you take care of it during and after installation, then there’s no reason why your decking shouldn’t last for at least a good few years.

Hazard or Use Class

The durability of timber depends a lot on the environment where it is being used. If your beautiful chest of drawers were left outside in the rain and snow it probably wouldn’t last as many years as in the dry bedroom it was originally designed for. That’s why we divide different environments into Use Classes (no longer called Hazard Classes):

| Use Class | Use Environment | Example of Timber Product |

|---|---|---|

| 1 | Dry, internal environments | Upper floor joists |

| 2 | Internal environment with slight risk of wetting | Tile battens |

| 3a | Outdoors, coated and above ground | Soffits / Cladding |

| 3b | Outdoors, uncoated and above ground | Fence rails / deckboard |

| 4 | Direct contact with soil or water | Fence posts or decking posts |

| 5 | Marine, continuous ground/water contact | Marine pilings |

As per the table above, for joists and decking that are going to last, you should always use timber that is naturally durable or that has been treated to Class 3b – but you must ensure there is no ground contact. Accordingly, use timber posts treated to Use class 4 if there’s direct ground contact. So now you know what to ask your supplier for when ordering your decking – joists and posts.

Slip resistance

There is an ongoing debate in the decking community regarding what is the best decking face: smooth or grooved. Thankfully, both are freely available, with the latter providing a more stable walking surface if the main direction of movement is across the decked area (not along the length of the deck board), and the former giving a clean look and feel. Note, however, that any decking can be given an anti-slip treatment and be fitted with quartz sand strips to protect you and your users in wet days.

These are particularly appealing to large area and public realm projects so are a favourite of councils and landscape architects and designers.

Fixing

Stainless steel screws are often used when fixing decking, but there are so many potential sizes that it’s important you know exactly what size suits your boarding. The usual practice is for screw lengths to be 2.5 times the thickness of your deck board. So if you’re installing a 21x145mm deck board, consider screws longer than 53mm.

Joists

The structure upon which your deck boards will rest, the joists, are as vital a part of the decking as the boards themselves as they are quite literally what holds everything together.

Whilst they are most often hidden from view, the joists need to be as durable as possible, as they are going to be the parts of the structure that take most of the weight. Apart from being from FSC® sustainable forests and suppliers, it is also vital that you check both the strength and the durability classes of the joists. Check span tables such as the one below to calculate the safe distance between joists.

Maximum softwood joist spans

(Metres) – Strength Class C16

| Joist centres (mm) | 400 | 500 | 600 | 400 | 500 | 600 |

|---|---|---|---|---|---|---|

| Type of deck | Domestic | Domestic | Domestic | Commercial | Commercial | Commercial |

| Dead load | ≤0.25NN/M² | ≤0.25NN/M² | ≤0.25NN/M² | ≤1.25NN/M² | ≤1.25NN/M² | ≤1.25NN/M² |

| 50 x 150 nominal joist size (mm) | 3.06 | 2.94 | 2.67 | 2.52 | 2.42 | 2.15 |

| 50 x 100 nominal joist size (mm) | 1.95 | 1.84 | 1.60 | 1.57 | 1.49 | 1.31 |

Above, you’ll find an example of the span tables for a C16 softwood joist. This marks the amount of load (weight per area) the joist can take and should always be considered when installing new decking.

The great British pier

Ever since iconic Brighton Pier burnt down in 2003, there has been a resurgence of optimism surrounding the good old fashioned British pier, with dozens being renovated across the country in the last two decades. Hastings Pier, for example, is a stunning construction that claimed the prestigious 2017 RIBA Stirling Prize and continues to draw in visitors from across the globe. Ecochoice supplied all the joists and deck boards in FSC Ekki.

Of course, this is just one example of where our decking has been used to create a gorgeous and sustainable public space, but there are hundreds more scattered across the country and more being built every week. You’ll find examples of some of them below, but that’s just the tip of the iceberg, so feel free to contact us today if you’re after something special.

Decking profiles

Grip-Choice decking

Ekki decking

Hardwood decking

Softwood decking

ThermoWood decking

Deck joists

Recycled Plastic decking

OrganoWood decking

WPC decking

Decking related insights

Whether you are building a raised deck or you are inspired by these ground-level deck ideas, there are some installation...

Iroko timber is one of the most durable timber species on the market, but that does not mean it is...

Leaving a gap between decking boards is standard practice when laying timber decking. But why? Whether you are taking on...

When constructing a timber deck, one crucial yet often overlooked detail is the spacing between decking boards. But, as anyone...

When choosing timber for an outdoor project, it is always wise to weigh up your options. This includes when designing...

Did you know that not all decking has to be raised? Ground-level decks sit perfectly flat with the rest of...