Different types of timber cladding profiles

Published: 13/01/20 By: Mike Bekin

Timber cladding has always been a popular choice for enhancing the exterior of buildings both big and small. The use of this all-natural, lightweight yet durable material ensures a warm, comforting, and truly beautiful finish that’s unrivalled by any other cladding material.

Whatever type of timber you use, its grain and colour adds an attractiveness that will make the building aesthetically pleasing for years to come in a natural and unique way. Timber cladding when correctly specified, installed, and maintained will stand the test of time too.

Timber cladding is a wonder product for many reasons, starting with the environmental advantages of using timber cladding on your upcoming project. As a renewable resource, timber cladding that’s FSC® certified and therefore sustainably sourced also has a low carbon footprint, can be reused or recycled, and therefore is a much better choice when compared with virtually any other alternative. Timber’s sheer choice of species, textures, and finish options available mean there’s something to please any project. However, selecting the right type of timber cladding for your design and budget can be difficult.

In this blog post, we showcase the timber cladding profiles most commonly used so you can easily find the right one for your requirements.

Feather edge

Feather edge is the most traditional looking profile. It is created by sawing a board diagonally along its length.

The resulting tapered boards can then be overlapped during fitting. This practice is similar to the technique used when fitting roof slates.

The feather edge profile is usually cheaper than most since you get double the cover from splitting each board in half. It is an excellent option for those looking for a more traditional or rustic finish since the face has a sawn appearance. For the real barn look you may choose the waney edge finish, where some of the bark is left on one side.

Usual species available in feather edge include oak, douglas fir, pine and Thermowood®.

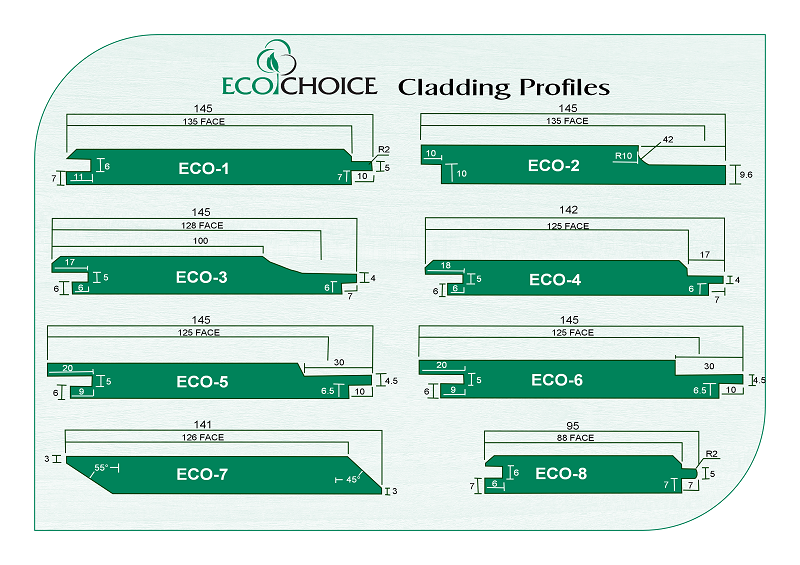

Shiplap (see eco-2 profile)

Shiplap timber cladding’s distinctive profile is machined to ensure a super smooth finish and overlap. This profile uses an overlapping edge detail to ensure complete water tightness. The shiplap laying style can be seen across modern and traditional properties, but was particularly popular during the 1960s and 1970s. It is thought to have been used in early shipbuilding with methods using a form of shiplap to construct the ship’s hull.

In the modern day, the overlapping characteristic of this profile is often used to hide the fixing screws, making them invisible as the next cladding board goes over and covers the lap.

A wide range of species are suitable for this profile, which also lends itself to both vertical and horizontal cladding. These include Siberian larch, western red cedar and spruce.

Tongue and groove (see 1, 3, 4, 5 and 6 profiles)

Tongue and groove is probably the most popular profile of timber cladding, with a wide range of face details such as shadow gap, TGV and others (see our cladding profiles for further details.

Although care is needed with the thin tongues during transport and installation, this profile will give a contemporary, uniform look that suits most modern properties.

The interlocking nature of tongue and groove profile cladding also helps with increased stability as each board is slotted onto the next. However, it is important to allow for good ventilation so that boards can naturally respond to variations in moisture. For this reason, kiln-dried timber is usually a better option for this cladding profile, making thermo modified wood one of the most suitable choices.

Half lap

Sharp and completely waterproof, half lap guarantees a clean and linear appearance that’s suitable for new builds and contemporary extensions added to period properties. Half lap has a bold finish that can further be enhanced by using thicker boards such as 33 or 50mm. It is often used as vertical cladding.

Splayed (see eco-7 profile)

The splayed or rainscreen cladding style consists of rhomboid shaped boards that are evenly spaced. Unlike the aforementioned profiles, splayed boards don’t fit together or interlock. Contrary to popular belief, they can be made waterproof if laid closely together, although it is usually the norm to have a dampproof membrane behind it. Once installed it makes for one of the most stunning profiles – see if you find a night picture of a building where the light comes through the cladding, it’s gorgeous.

Splayed cladding has increased benefits especially in warm countries. Buildings with splayed cladding require less maintenance, have better thermal performance and benefit from an improved aesthetic appearance.

The final flourish?

Once you’ve chosen the right profile for you, it’s time to look at the various cladding finishes available. Here the Timber Decking and Cladding Association (TDCA) offers their advice:

“In order to deliver the desired service life, any coating applied must be maintained in good condition in accordance with the manufacturer’s guidance. The ease of access and requirement for maintenance will largely determine what product is selected. Surface coatings work best on timbers that are dimensionally stable or have a low potential for moisture change movement. Surface texture is also important and coatings generally perform better applied to sawn rather than smooth planed timber.”

Fixing is also another matter for consideration, with two face screws (preferably stainless steel) usually providing the best solution. More information is available on our cladding guide from Trada.

Whatever laying style or finish you opt for, make sustainable timber cladding your first choice. Call us today on 0345 638 1340, or email info@ecochoice.co.uk for a free, no-obligation quotation. You can also check out our dedicated timber cladding profiles page for further details.

Tags: Cladding, Durability, Sustainability, Timber

Categories: Insights