From glulam to CLT – laminated timbers explained

Published: 31/08/20 By: Mike Bekin

Laminated timber is being used more and more often in the construction industry. Strong, sustainable and attractive, it offers a range of benefits over other building materials. Here, we take a closer look at some of the most popular forms of laminated timber available.

Glulam

Glulam is one of the oldest forms of laminated timber used in construction. Patented in the 19th century, glulam is made up of layers of timber glued together using a super-strong adhesive. The layers of wood used to make glulam are all orientated in the same direction. This allows glulam beams to shrink and expand just like solid wood.

CLT

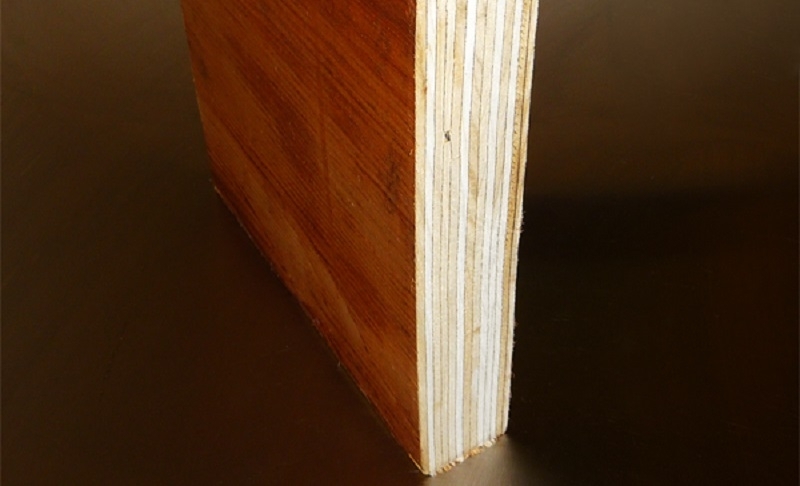

Cross-laminated timber, or CLT, is incredibly strong and stable as it’s glued perpendicular to the grain – like an over-sized sheet of plywood. One of the most popular types of laminated timber used in modern construction, it’s used for everything from walls and floors to roofs and beams. Its strength and longevity make CLT very versatile and it’s now a favourite for many in the building industry. As @Treehugger explains, “First introduced in the 1990s, it enables architects and engineers to design tall, fire-safe and beautiful wood buildings.”

NLT

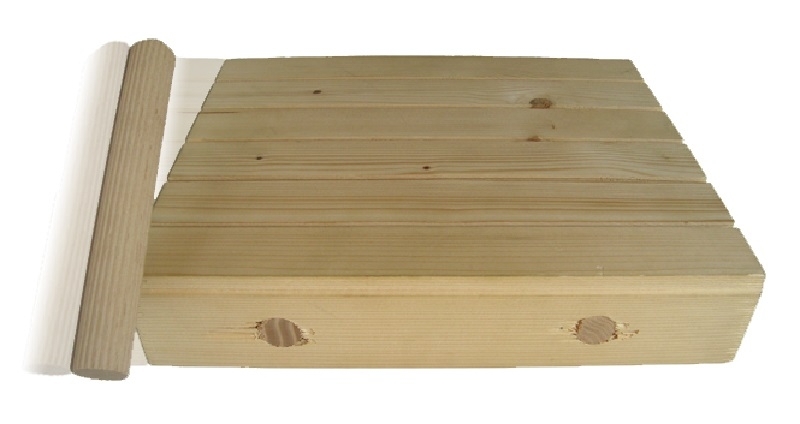

NLT is an affordable and easy to produce a form of laminated timber. Once known as mill decking or heavy timber, NLT – or Nail Laminated Timber – is made by simply nailing wooden boards together. As more and more layers are built up, the NLT gets stronger and stronger. The finished product can be used to build everything from walls and ceilings to entire buildings.

DLT

One of the downsides of NLT is that it’s full of nails. While this makes the material very strong, it also means it can be difficult to work once it’s in place. Dowel-laminated timber, or DLT, on the other hand, uses wooden dowels instead of nails to hold layers of timber together. The system works by utilising the variation in moisture content between the posts and dowels. Softwood posts are dried to a moisture content of 12-15%, while hardwood dowels are dried to a moisture content of 8%. When the hardwood dowels are inserted in the softwood posts, the differing moisture content causes the dowels to expand and lock the posts together.

One of the downsides of NLT is that it’s full of nails. While this makes the material very strong, it also means it can be difficult to work once it’s in place. Dowel-laminated timber, or DLT, on the other hand, uses wooden dowels instead of nails to hold layers of timber together. The system works by utilising the variation in moisture content between the posts and dowels. Softwood posts are dried to a moisture content of 12-15%, while hardwood dowels are dried to a moisture content of 8%. When the hardwood dowels are inserted in the softwood posts, the differing moisture content causes the dowels to expand and lock the posts together.

LVL

Laminated veneer timber, or LVL, is made by glueing together thin layers of veneer. As with glulam, all the grain runs in the same direction. High performance engineered hardwood LVL allows beams and columns to have smaller cross-sections than softwood glulam. This can help to make buildings appear lighter and more elegant.

Find out more about laminated timber, and sourcing sustainable wood, by exploring our site today.